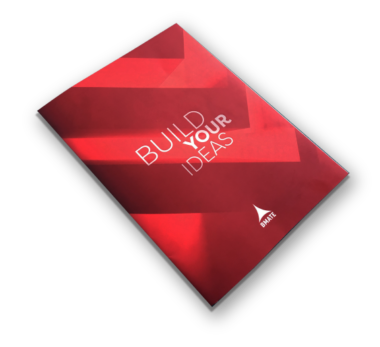

INDUSTRIALIZATION

Industrialization is a crucial phase for achieving the economic success of an idea.

The objectives to achieve in order to turn your prototype into a product are:

- Reduction of production and maintenance costs

- Performance optimisation

- Achievement of the desired level of reliability

- Environmental sustainability/End-of-life management

- Ergonomic design.

We help you in this phase, fully managing the entire process. The network of our partners and affiliates is able to analyse every aspect of the prototype and deliver to you an engineered product from all points of view. Every complex product in which electronics, mechanics and software are connected and inter-functional is managed on the basis of these principles:

- Simplification: only necessary components and functions

- Standardisation: optimisation of inventory codes

- Integration: obtain the best functional result

- Rationalisation: maximum efficiency in the use of resources.

Cost Saving

Savings on costs for putting a project into production, whatever it is, is a fundamental condition for the profit of the project. We help you to avoid launching production with a costly cycle, including unnecessary phases or phases performed in an inefficient manner.

Our value is being able to accompany you in the industrialisation process in order to deliver effective savings.

We analyse every production phase and every significant component, suggesting all the necessary project modifications to obtain a production process able to generate more profit.

Optimisation

We are able to work on finished projects to analyse all the phases and identify possibilities for optimisation.

Once the design or the process has been examined and fully understood, it is broken down into its main phases; these, in turn, are analysed to identify possible optimisation strategies.

With a top-down approach, every component, sensor or processing phase are examined in detail to establish whether they are essential or improvable.

We will deliver you a finished project which is more competitive in production and easier to maintain.

Reliability

The reliability of an industrial product is decisive!

A key factor for standing out from competitors is the soundness of the product. Reaching a high level of reliability is a process that starts from far off, directly from the conception of the idea and its initial design phases.

We take these aspects into consideration right from the start of our work and we seek to improve reliability also for projects and products not designed by us.

The breadth of our know-how allows us to deal with the design of advanced diagnostics and predictive maintenance systems, integrating cutting-edge technologies in any industrial sector to make every product truly 4.0.

Supply Chain

We coordinate and manage in the best possible way every production process for your idea. Efficiency, effectiveness and time-to-market are the principles characterising and guiding all our actions.

Thanks to our experience in various sectors, we can suggest advantageous selected suppliers in terms of quality and/or cost, for the production or for the purchase of components, both to drawings and commercially marketed.

We operate autonomously but, when requested, we are able to flank you for single aspects or we can take on the role of coordinator of supply chain in addition or replacing specific company figures.

We coordinate and manage relations inside and outside the company, so as to ensure a rapid and optimised process in all its aspects.

Documentation

Documentation, manuals, certifications and approvals are taken care of in every detail.

The documentation of a project is an added value not to be undervalued. The operator’s and technical manuals are often the first contact the user has with a product; the quality of these documents forms part of the overall quality of the product itself.

We manage the documentation during the entire evolution of the project, with professionalism and expertise, remaining always aligned with the latest technological developments to guarantee you a technical-specialist documentation of quality.

- Technical manual

- Operator’s manual

- Interactive manuals

- Exploded assembly drawings

- 3D videos with installation and maintenance instructions.

INDUSTRIALIZATION AS A BASIS FOR SUCCESS

Find out how the Industrialisation could be the basis for your success.